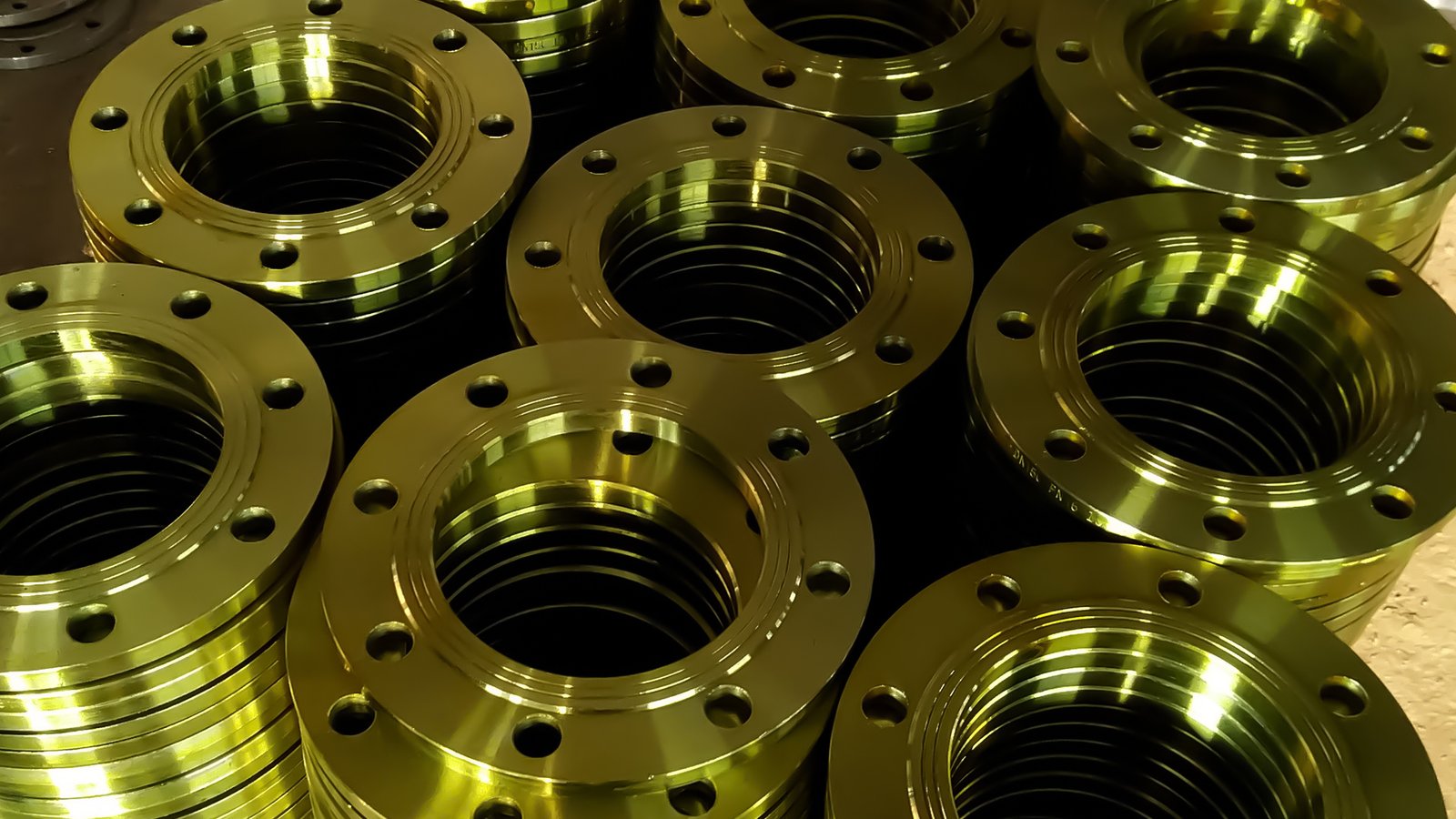

In piping and engineering systems, flange precision plays a key role in preventing leakages, ensuring alignment, and maintaining long-term durability. This is where CNC machining transforms ordinary flanges into high-performance engineered components.

What is CNC Machining?

CNC (Computer Numerical Control) uses computer-controlled machines to cut, drill, and finish metal with high precision ensuring perfect accuracy in every flange.

Why CNC Flanges Perform Better

1. Dimensional Accuracy : CNC ensures 100% precise centre alignment, bolt-hole spacing, and thickness. Prevents leakage and reduces gasket wear.

2.Superior Surface Finish : Smooth flange face = better sealing and no uneven gasket pressure.

3.Perfect Repeatability : Whether 10 pieces or 10,000 – every flange maintains the same dimensions.

In modern industrial projects, precision is not a luxury – it’s a necessity.

CNC machined flanges ensure maximum reliability, longer performance, and perfect sealing.